|

Ridecon adopt international advanced system - CAD/CAM/CAE in mould design and processing. We use professional software such as Pro-Engineer, Solidworks, Unigraphics. Customer provide the 2D drawing or 3D data in DXF, DWG, PRT, SAT, IGES, STEP format etc, or just send us the sample. We will scan the sample and make product blueprint, begin to design the mould assembly drawing just after customer confirm the blueprint, and customize the existing project. We will offer the mould assembly drawing for customer further discussion when necessary, considering about product parting line, gate, ejector position, water cooling layout, moving direction and distance of slide etc, then define a solution with which customer is the most satisfied.

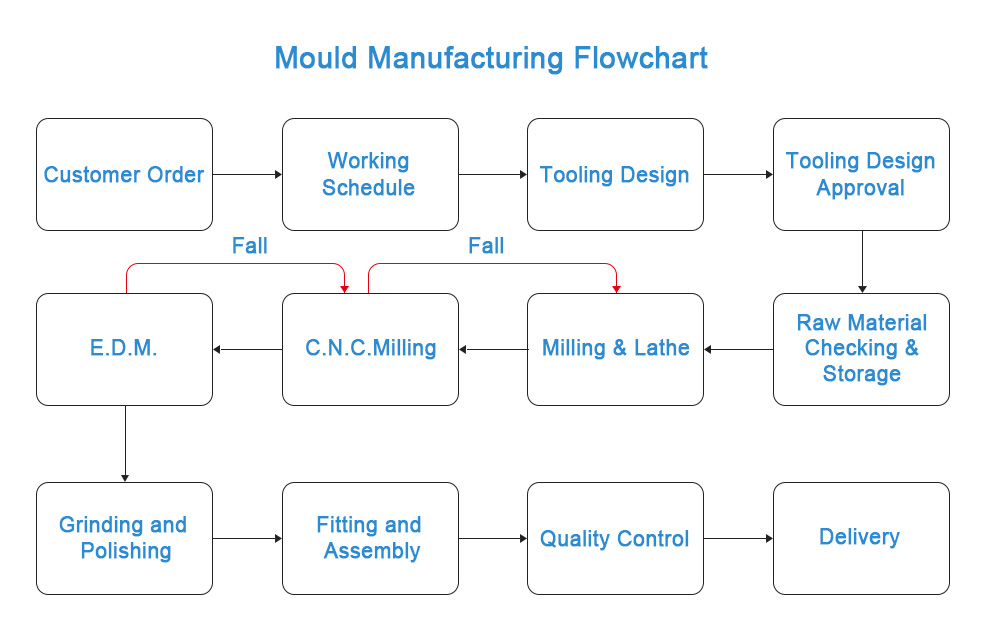

Die/Mold making flow chart:

Die/Mold material options:

718, 738, S136 from ASSAB of Sweden, NAK80 from DAIDO of Japan and P20, 420. Most mould bases and standard components come from LKM. At the same time, we can design mould according to customer’s requirement, such as DME, HASCO.

Die/Mold Shipment:

After the final confirmation to mould by customer, we will pack the mould with standard exporting package to avoid any damage during the long distance delivery by sea or by air. There are the trial samples, trial report and some replaceable parts provided at the same time.

Every mould components will be produced and checked strictly according to separate standard drawing. When the mould is exported, we can send the full set of mould assembly drawing and components drawing to customer for their information supplement, it is a value-added service and totally fee-free.

|